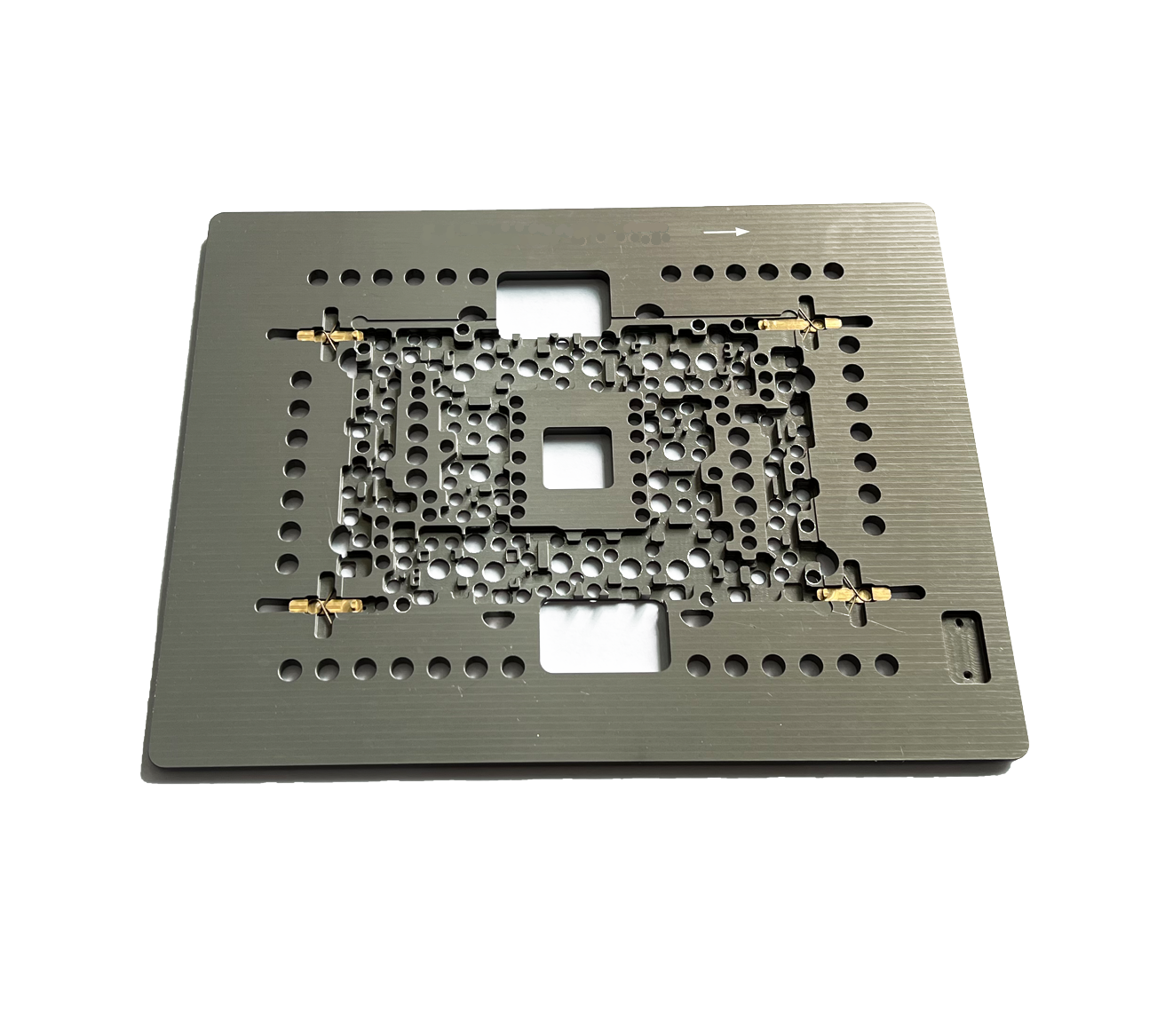

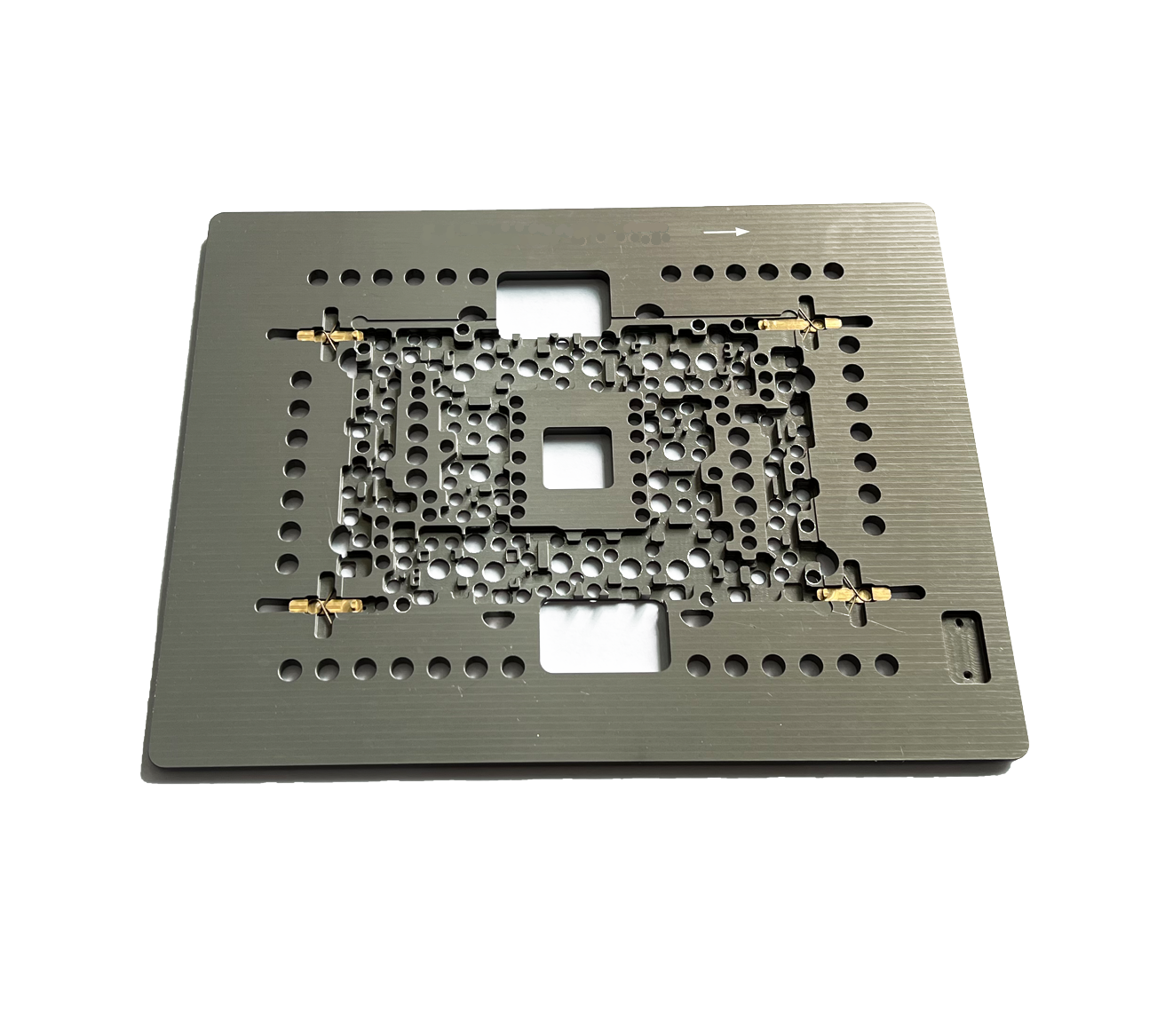

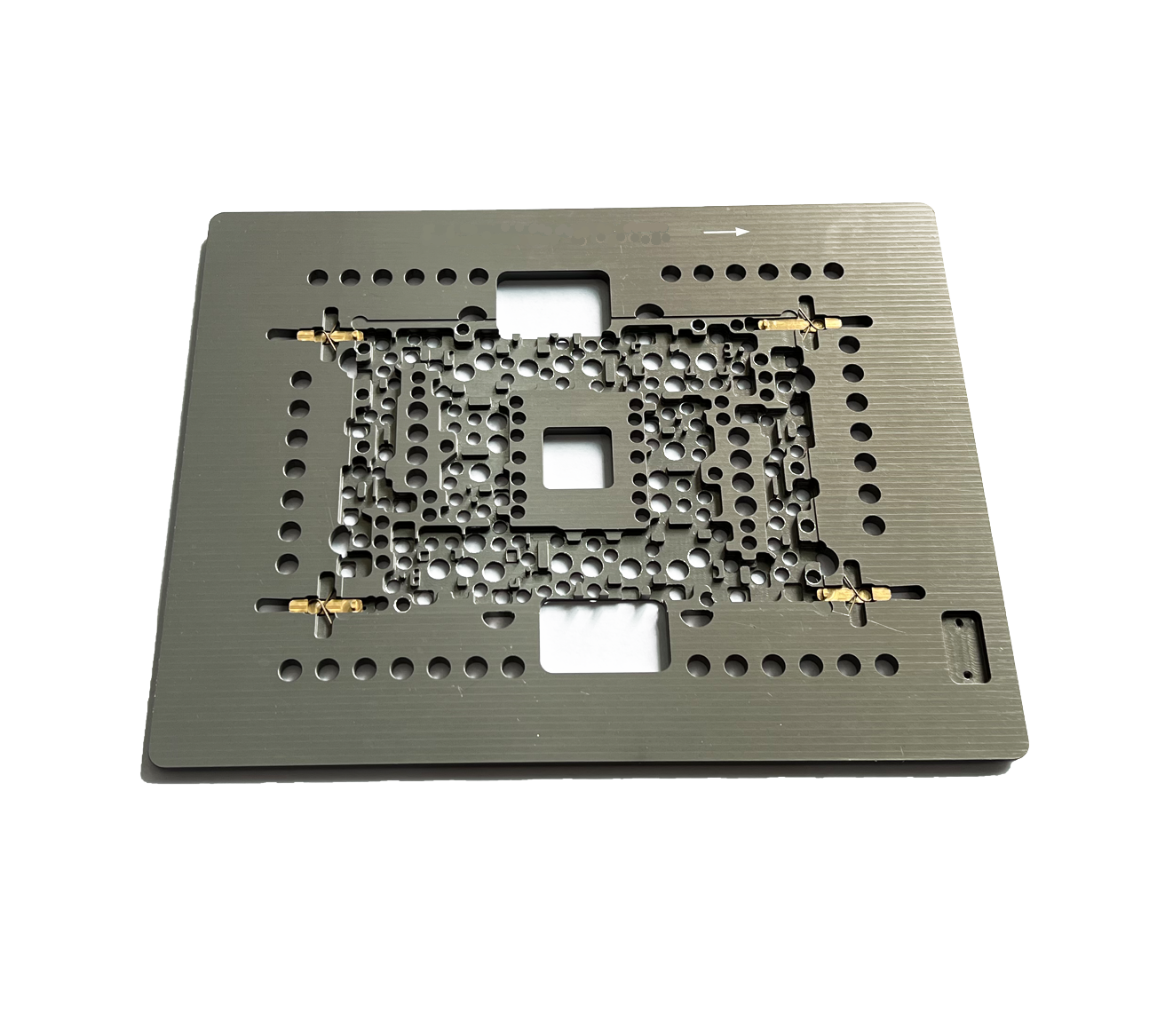

PCB board adhesive precision machining parts

Product details:

Place of origin:

China

Brand name:

Customized

Certification:

RoHS, ISO9001

Tolerance:

+/-0.002mm

Payment & Shipment terms

Delivery time:

5-10 Working days

Packaging details:

Normal

Price:

Mode of payment:

L/C, T/T, Western Union, Paypal, D/A, D/P

Supply Ability:

1-More pcs

Product description

| Material | Steel, Aluminum, Brass, Plasic | Application: | Mechanical equipment, Automatic equipment, Precision die mould, precision jig, precision gauge, electronics, Medical...etc |

|---|---|---|---|

| Tolerance | +/-0.002mm | Processing equipment | CNC/Grinder/EDM Heat Treatment Equipment/Drilling Machine |

| Transport package | Standard Export Carton Or Customized | Export Port | Shen Zhen |

Case Presentation

Case Presentation

Case Presentation

Get detail quickly

| Material | Stainless Steel ,Aluminum , Brass , Steel , Iron , Bronze , Titanium , copper , Magnesium , Plastic |

| Tolerance | +/-0.002mm |

| Size | Customized |

| Color | Primary / black / white / red / Sliver / yellow in general |

| Application | Mechanical equipment, Automatic equipment, Precision die mould, precision jig, precision gauge, electronics, Medical...etc |

| Delivery | 5-10 working days |

| Package | Standard Export Carton Or Customized |

| Certification | RoHS, ISO9001 |

| Minmum order quantity | 1 pcs |

Product Presentation

Machined parts is a custom - made service . Apply to Automobile, Motorcycle, Bicycle, Scooter , Aerospace ,Machinery, electronics, Medical , 5G ,Furniture, Construction, Autoamtion and other industrial uses

About US

| Business Type | Manufacturer | |

| Our Advantages | 1. Juffon is factory providing machining ,Stamping ,design service for more than 10 years, we focus on client's demand and client's satisfaction 2. Provide 2D & 3D drawing for modifying 3. Competitive price with good quality 4. Small order is acceptable 5. Short delivery time (7-25days according to order Qty) 6. Customized size and specification /OEM available 7. Near Shenzhen and Guangzhou, convenient transportation |

|

| Application | Automobile, Motorcycle, Bicycle, Scooter, Aerospace ,Machinery, electronics, Medical , 5G ,furniture, construction and other industrial uses | |

| Materials | Stainless Steel | SS201, SS303, SS304, SS316 etc |

| Steel | Q235, 20#, 45# etc | |

| Brass | C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37) , C28000(CuZn40) etc | |

| Iron: | 1213, 12L14,1215 etc | |

| Bronze | C51000, C52100, C54400, etc | |

| Aluminum | Al6061, Al6063,AL7075,AL5052 etc | |

| Titanium | Gr1, Gr2, Gr3, Gr4,Gr5, Gr7, Gr9, Gr11, Gr23, etc | |

| Magnesium | AZ31, AZ61, AZ91,etc | |

| Plastic | ABS,PC,PE,POM,Nylon,Teflon,PP etc | |

| Machining | Turning, Milling, Drilling, Grinding, Cleaning, electrosparking, stamping, sheet-metal working, Assembling | |

| Main Equipments | CNC lathe, CNC milling, Stamping machine, Automatic lathe, Grinder, Tapping machine, Drilling machine,Electric discharge machine, Leser cutting machine, Bending machine, CNC Punching machine...etc | |

| Measuring & Testing equipments | CMM, Profile Projector, Rockwell Hardness Tester, Vickers Hardness Tester, Roughness Tester, Micrometers, height gauge, Calipers... etc. | |

| Accuracy | Accuracy Of Machining:+/-0.002mm | |

| Accuracy Of Grinding:+/-0.002mm | ||

| Surface Roughness:Ra0.5 | ||

| Parallelism:+/-0.002mm | ||

| Verticality:+/-0.002mm | ||

| Concentricity:0.002mm | ||

| Polishing, Deburring, Chrome Plating, Ni Plated, Zinc plated, Silver platinng,Anodizing various colors, Carburizing Nitriding, Heat Treatment, etc… | ||

| Surface Treatment: | ||

These precision - machined parts are the result of advanced manufacturing techniques. Manufacturers are investing significant resources in research and development to ensure the highest quality of these components. China, known for its vibrant electronics manufacturing sector, has numerous companies specializing in the production of PCB board adhesive precision machining parts.

The precision machining of these parts is crucial for several reasons. Firstly, when it comes to PCB boards, the adhesive parts need to be machined with extreme accuracy. This ensures proper adhesion and mechanical stability within the circuit board assembly. The parts are often designed to fit into very specific spaces on the PCB, and any deviation in their dimensions can lead to malfunction or reduced performance of the entire circuit board.

These parts are made from a variety of materials, carefully selected based on their properties such as conductivity, heat resistance, and chemical stability. High - quality adhesives are used to bond these parts to the PCB board, and the precision machining ensures that the adhesive is applied evenly and in the correct amount.

In the manufacturing process, state - of - the - art CNC (Computer Numerical Control) machines are often employed. These machines are capable of achieving micron - level precision, allowing for the production of complex and highly accurate PCB board adhesive precision machining parts. The use of CNC machines also enables mass production while maintaining consistent quality.

The demand for these parts is on the rise, driven by the continuous growth of the electronics industry. From consumer electronics like smartphones and tablets to more complex industrial and automotive electronics, PCB board adhesive precision machining parts are essential. For example, in automotive electronics, where reliability is crucial, these precision parts contribute to the proper functioning of various control systems within the vehicle.

Many manufacturers are also focusing on environmental sustainability in the production of these parts. They are exploring ways to use more eco - friendly materials and reduce waste during the manufacturing process.

In conclusion, PCB board adhesive precision machining parts are a cornerstone of modern electronics manufacturing. Their high - precision machining and reliable performance are enabling the development of more advanced and efficient circuit boards, which in turn are powering the ever - evolving world of electronics.

Our Advantage:

1. 90% standard parts will be shipped within 3 days.Assembly products can be delivered according to customer requirements Customized products can be negotiated according to customer demand delivery date

2. Non-standard drawing customization.velop new products according to demand

3. Strict internal quality management system.Comprehensive supplier quality management system

4. The whole series of products have 3D models,Calculation and selection support to improve design efficiency.Pre-sales support and after- sale technical training services

Frequently Asked Questions :

1.How long and how can I get quotation from your company?

We will reply you in two hours if getting detailed information during working days.

In order to quote you as soon as possible, please provide us the following information together with your inquiry.

1). Detailed drawings (CAD/PDF/DWG/IGS/STEP/JPG)

2). Materials required

3). Surface treatment

4). Quantity (per order/per month/annual)

5). Any special demands or requirements, such as packing, labels,delivery,etc.

2.Can I get samples for testing?

We can offer free samples for small parts, but for big and high-value products, samples will be charged.

3. How about the payment terms?

For new customers, we prefer to use T/T in advance. We can accept L/C, D/P for old customers.

4. If I need urgent delivery, can you help?

Of course! Customer first is our company philosophy. You need to tell us the delivery time when placing the order, and we will do our best to adjust the production schedule

5.How about the transportation?

You can choose any mode of transportation you need, sea delivery, air delivery or express delivery.

6. How about the quality guarantee?

We will make 100% inspection before packing and delivery and make sure the products 100% meet your requirements . If there is any problems during using, please tell us anytime, we will reply you in time

7.Can we sign NDA?

Sure. We never divulge any customer's information to anyone else.

8. Delivery and payment

Packaging and transportation: carton, wooden box (size can be negotiated)

Contact us

Shen Zhen Juffon Precision Intelligent Techology Co., Ltd

Contact UsRelated products